To keep industrial equipment running and avoid unplanned downtime you can employ automatic testing and self-diagnostic tasks to continuously assess and prevent issues in real-time.

This use case is valid for equipment that includes turbines, generators, transformers, pumps, fans, rotors, tanks, relays, or pipes, but also smaller machinery which you can automatically monitor with the help of devices such as sensors or robots, that can send data to your main controls and alerts systems.

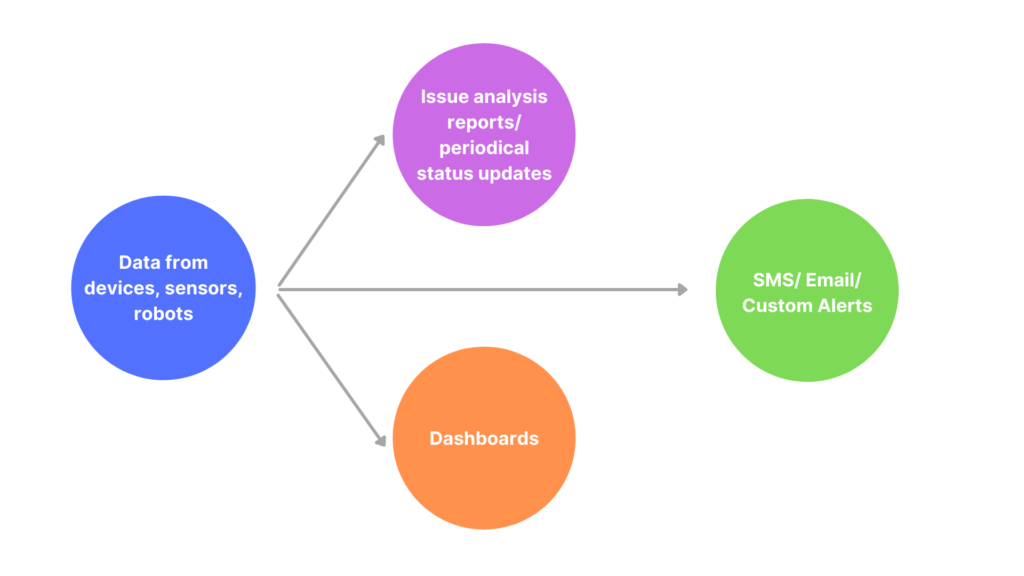

In PROCESIO you can set up a workflow that receives data from the hardware devices and automatically issues alerts to operational/ ground teams or managers, creates analysis reports/ periodical status updates, and displays data in centralised dashboards.

- Connect to devices using Call API actions or Webhooks

- Create the data model

- Set up the process variables

- Send data to specific software or dashboards using Call API

- Use the Json mapper if you are working with data in Json format

- Issue reports/ status updates (could also be in PDF, CSV or XLSX format using templates)

- Use the Call API action to set up custom alerts, SMSs, and the Send Email action for emails

Benefits of automating testing and diagnostics

- Reduce costs from maintenance or periodic manual testing

- Prevent outages and shorten repair times

- Continuous monitoring compared to periodical manual checks

- Get detailed test results which you can also use as detailed documentation for regulatory bodies